High efficiency of CNC surface drilling machine

High efficiency of CNC surface drilling machine

Choosing digital control equipment is like buying a car. The price should be appropriate, the quality should be reliable, and the appearance should be beautiful.

We purchase numerical control equipment first according to own processing work piece material, the specification, the thickness, the drill diameter, the processing quantity size, the drill type, the precision and so on selects the price suitable, the quality reliable, the work efficiency high numerical control equipment.

Liu is the head of a pressure vessel manufacturing plant, the former home of tube plate processing is done on the radial drill, crossed a cumbersome, proofing and so on working procedure, for 1600 x1600x30 tubesheet machining, often work overtime all finish, and manual processing of low efficiency, high cost, the quality of the drilled hole is coarse, machining accuracy is not very good, also is very upset. Through chatting, the customer service staff of times over recommended the CJ1616HZ CNC high speed drilling and milling machine, which not only improved the processing efficiency and precision, but also saved a large amount of labor costs.

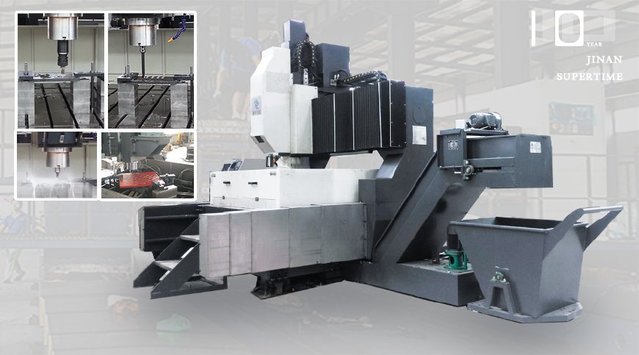

Let's have a look at the flat plate, tube plate processing profit --CJ1616HZ CNC high speed drilling and milling machine

CJ1616HZ type gantry mobile high-speed CNC drilling and milling machine is mainly used for drilling and milling of plate workpieces in the steel structure industry, such as construction, bridge, iron tower, etc. This product is used for drilling through hole, blind hole, step hole, hole end chamfer and workpiece milling. The maximum processing range is 1600 x 1600mm.

A device that can not only meet your current flange drilling post and can be used to drill on the tube plate to kill two birds with one stone is a good choice in the long run!

Features of machine:

1. The high-speed numerical control drill adopts the numerical control sliding pillow power head (Z axis), and the stroke is preset according to the workpiece, which can realize the automatic conversion of the bit's fast-leading-to-work-leading-back. It has the advantages of high machining efficiency, simple structure and low maintenance cost. Compact structure, easy to use, simple maintenance.

2. The power head spindle of the machine tool adopts Taiwan BT40 precision inner cold rigidity spindle, which can use carbide inner cold bit with high precision. Equipped with hydraulic tool cylinder, loading and unloading tool is very convenient. The spindle is driven by high-power spindle motor through synchronous belt. The spindle speed is 30 ~ 3000r/min, with a wide range of speed.

3. CJ1616HZ gantry mobile high-speed CNC drilling and milling machine has 3 CNC axles: gantry movement (x axis); Movement of the power head on the beam of the gantry (y axis); Feed motion of the power head (z axis). Each CNC shaft is driven by precision linear rolling guide rail, AC servo motor and ball screw. Flexible movement and accurate positioning.

4. A number of transverse t-shaped slots are arranged on the plane of the work table for mounting clamps and workpieces.

5. The machine is equipped with a flat-plate chain automatic chip ejector and chip collecting machine to collect iron filings and cutting fluid.

6. Automatic lubrication system is provided for high-precision moving pairs such as machine tool precision linear roller guide rail and precision ball screw.

7. The numerical control is controlled by Siemens 808D, and equipped with upper computer to facilitate the storage and input of the workpiece processing program, with easy operation.

8. CJ1616HZ gantry mobile high-speed CNC drilling and milling machine equipped with ball screw pair, linear guide rail pair, electrical parts, servo motor, frequency converter, etc., are supplied by well-known manufacturers at home and abroad, with few starting failures.

Main technical parameters of CJ1616HZ gantry mobile high-speed CNC drilling and milling machine:

Maximum effective machining range (length * width) : 1600X1600mm;

Maximum thickness of workpiece: 120mm

Maximum diameter of hole: 40mm

Speed: 6000 r/min

Overall dimensions (length X width X height): about 3900X4500X3000mm

Machine weight: about 12t

Advantages of CJ1616HZ gantry mobile high-speed CNC drilling and milling machine:

1. The power head spindle of the machine tool adopts BT40 internal cold rigidity precision spindle, which can use carbide internal cold cutting tools with high accuracy and efficiency. And equipped with hydraulic tool cylinder, loading and unloading tools is very convenient. The spindle is driven by high-power spindle motor. The spindle speed is 30 ~ 3000r/min, with a wide range of speed.

2. By optimizing the design, the rigidity of the machine tool can be improved so that the machine tool can be used for both drilling and milling and tapping.

3. The numerical control is controlled by Siemens 808D, and equipped with upper computer to facilitate the storage and input of the workpiece processing program, with easy operation.

4. The ball screw pair, linear guide rail pair, electrical parts, servo motor, frequency converter etc. equipped with the machine tool are supplied by well-known manufacturers at home and abroad, with few start-up failures.