Analysis of future development direction of nc machine tool facing market competition pressure

Analysis of future development direction of nc machine tool facing market competition pressure

Numerical control machine tool is an important basic equipment of machine tool manufacturing. In recent years, China's machine tool manufacturing industry is facing both the opportunity of manufacturing equipment development and the pressure of market competition. From the perspective of technology, accelerating CNC technology will be a key to the sustainable development of machine tool manufacturing. At present, the world's advanced manufacturing technology is constantly emerging, the application of ultra-high-speed cutting, ultra-precision machining and other technologies, the rapid development of flexible manufacturing system and the continuous maturity of computer integration system, which put forward higher requirements for the numerical control processing technology. Today the numerical control machine tool is developing in the following directions.

1.Maximum reliability

The reliability of nc machine tool is the main index that user CARES most all the time. The numerical control system will adopt more integrated circuit chips, and use large-scale or super-scale specialized and hybrid integrated circuits to reduce the number of components to improve reliability. The hardware function is softwarised to meet the requirements of various control functions, and the hardware structure is adopted to modularize, standardize, generalize and serialize the machine tool body, which not only improves the batch quantity of hardware production, but also facilitates the organization of production and quality control. It also realizes fault diagnosis and alarm of hardware, software and various external equipment in the system by automatically running various diagnostic procedures such as startup diagnosis, online diagnosis and offline diagnosis. Use alarm to prompt and remove failure in time; Using fault-tolerant technology, the "redundancy" design is adopted for the important parts to realize the self-recovery of fault. Using various testing and monitoring technologies, automatic protection is provided when production overruns, knife damage, interference, power failure and other accidents occur.

2. Miniaturization of control system

The miniaturization of numerical control system facilitates the integration of machine and electrical device. At present, it mainly adopts super-large scale integrated components, multi-layer printed circuit board and three-dimensional installation method, so that electronic components can be installed in high density and occupy space for large-scale reduction system. The use of new color liquid crystal thin display instead of the traditional cathode ray tube will make the nc operating system further miniaturization. In this way, it can be conveniently installed on the machine tool equipment, which is more convenient for the operation of the CNC machine tool.

3.Intelligent

Modern CNC machine tools will introduce adaptive control technology to automatically adjust the working parameters according to the change of cutting conditions, so as to maintain the best working state in the processing process, so as to obtain higher machining precision and less surface roughness, and at the same time, improve the service life of the cutter and the production efficiency of the equipment. It has the function of self-diagnosis and self-repair. In the whole working state, the system can make self-diagnosis and check the CNC system itself and various devices connected with it at any time. In case of failure, take measures such as stopping the machine immediately, and give a fault alarm, indicating the location and cause of the fault. The fault module can also be automatically taken offline, while the standby module can be switched on to ensure the requirements of the unmanned working environment. In order to achieve higher fault diagnosis requirements, the development trend is to use artificial intelligence expert diagnosis system.

4. CNC programming automation

At present, CAD/CAM graphic interactive automatic programming has been widely used, which is a new trend of numerical control technology development. It is the machining drawing of parts by CAD, and then calculated and postprocessed by the cutter track data in the computer, so as to automatically generate NC parts machining program, and realize the integration of CAD and CAM. With the development of CIMS technology, the automatic programming method of CAD/CAPP/CAM integration has emerged at present. The biggest difference between it and CAD/CAM system programming is that the processing process parameters required for its programming need not be manually involved, but directly obtained from the CAPP database in the system.

5. High speed and high accuracy

Speed and precision are two important indexes of nc machine tool. At present, the numerical control system adopts the processor with higher number and frequency to improve the basic operation speed of the system. At the same time, the super-large scale integrated circuit and multi-microprocessor structure are adopted to improve the data processing capability of the system, that is, to improve the speed and precision of interpolation operation. The linear servo feed mode of the machine table driven by linear motor is adopted. Feedforward control technology is adopted to greatly reduce the tracking lag error and improve the machining accuracy of corner cutting.

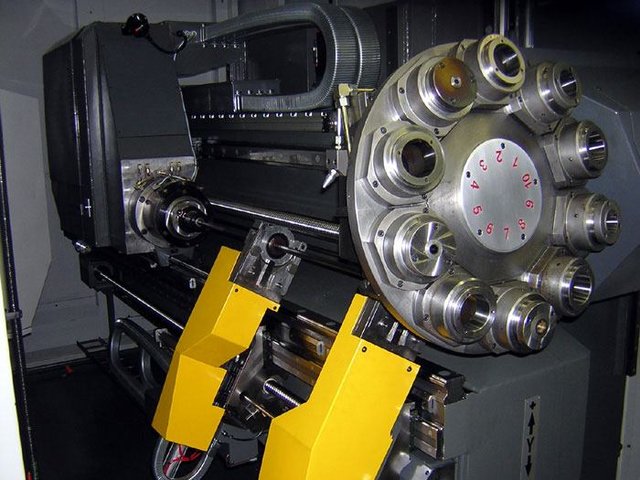

6. Multi-functionalization

Equipped with automatic tool change (dao database is up to 100 or above) of all kinds of processing center, can simultaneously on the same machine tools milling, boring, drilling, cutting, reaming, reaming and tapping screw thread, and other process, modern CNC machine also used the multiple spindle, polyhedron cutting, namely to a component at the same time in different ways in different parts of machining. The numerical control system, which adopts multi-cpu structure and hierarchical interrupt control, can process parts and program at the same time on a machine tool to realize the so-called "front-end processing and back-end editing". In order to meet the requirements of flexible manufacturing system and computer integration system, the nc system has a remote serial interface and can even be connected to the Internet to realize data communication between CNC machine tools, and can also directly control multiple CNC machine tools.

In order to meet the requirements of ultra-high-speed machining, the CNC machine tool adopts the structure of the combination of spindle motor and machine tool spindle, realizing the integration of variable-frequency motor and machine tool spindle.

Numerical control machine has attracted worldwide attention for its excellent flexible automation performance, excellent and stable accuracy, and flexible and diversified functions. It has pioneered the development of mechanical products towards electromechanical integration. Therefore, numerical control technology has become a core technology in advanced manufacturing technology. On the other hand, the deepening application of information technology promotes the further improvement of CNC machine tools through continuous research.